Pilot Insulator Pin / Transmission Insulator Pins

Pilot Insulator Pins and Transmission Insulator Pins are components used in electrical power transmission systems, specifically in overhead lines. They serve to electrically insulate the conductors from the supporting structures, such as poles or towers, and to support the weight of the conductors.

Share:

Product Description

Product Overview:

Pilot Insulator Pins, also known as Transmission Insulator Pins, are critical components used in overhead transmission and distribution systems. These pins are designed to securely attach insulators to utility poles, cross-arms, or other structures, ensuring the stability and reliability of electrical systems. Made from high-strength materials and treated for corrosion resistance, Pilot Insulator Pins are essential for maintaining the integrity of power distribution networks.

Structural Features:

High-Strength Material:

Constructed from durable materials such as forged steel, malleable iron, or aluminum alloy, providing exceptional strength and longevity.

Corrosion Resistance:

Often treated with hot-dip galvanization or other anti-corrosion coatings to protect against rust and environmental degradation, ensuring long-term performance.

Design:

Available in various designs to accommodate different types of insulators (e.g., pin-type, suspension-type). The pin typically features a threaded or smooth shaft for secure attachment.

Threaded End:

The threaded end allows for easy and secure installation of insulators, ensuring a tight fit and stable connection.

Installation Method:

Preparation:

Ensure all necessary tools and materials are available before starting the installation process. Verify the specifications of the Pilot Insulator Pin to ensure compatibility with the insulators and structures being used.

Positioning:

Position the insulator pin at the desired location on the utility pole, cross-arm, or other structures.

Securing the Pin:

Insert the pin through the pre-drilled hole in the structure and secure it using appropriate nuts and washers. Tighten the nuts securely to ensure a firm connection.

Mounting the Insulator:

Screw or attach the insulator onto the threaded end of the pin, ensuring it is tightly secured.

Inspection:

Inspect the installation to ensure the pin and insulator are securely fastened and properly aligned. Check for any signs of wear or damage.

Applicable Environmental Conditions:

Temperature Range:

Suitable for operation in temperatures ranging from -50°C to +150°C, ensuring performance in extreme weather conditions.

Humidity:

Effective in environments with high humidity, providing reliability in moist conditions.

Weather Resistance:

Designed to withstand harsh weather conditions, including high winds, heavy rain, snow, and UV exposure.

Corrosive Environments:

The anti-corrosion coatings provide excellent resistance to corrosion, making the pins suitable for environments exposed to salt, chemicals, or industrial pollutants.

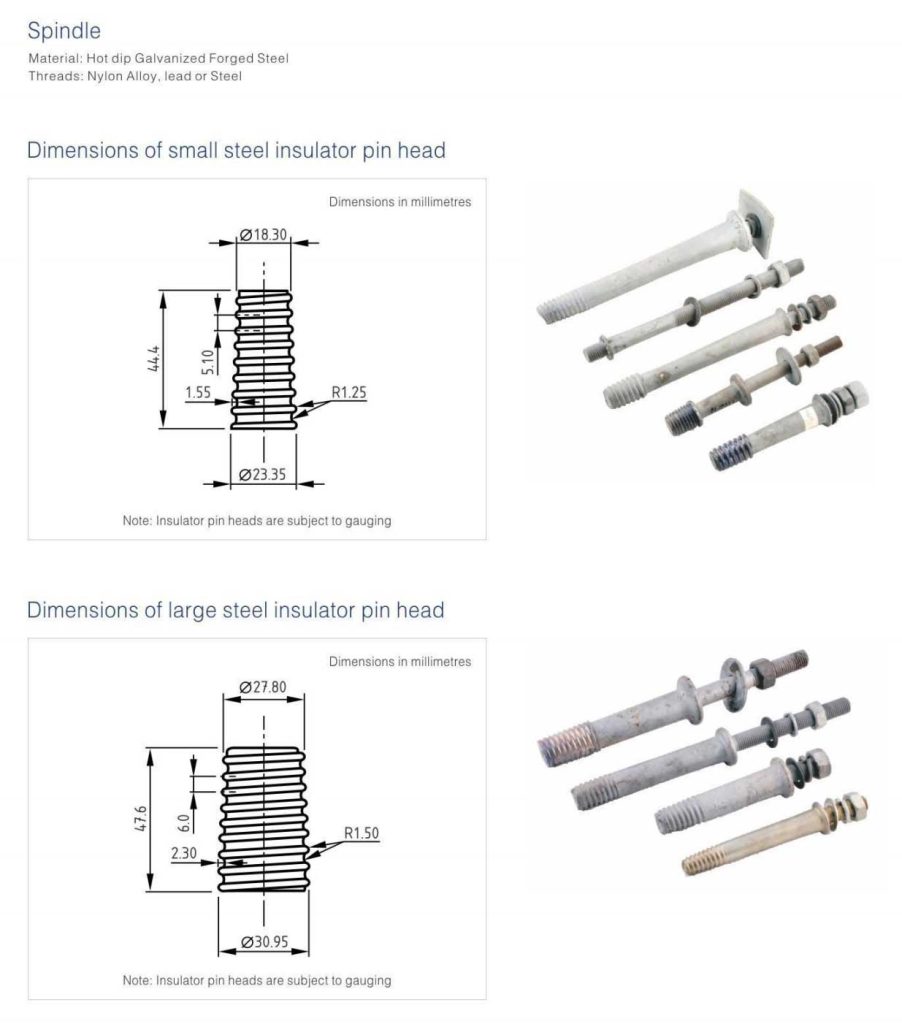

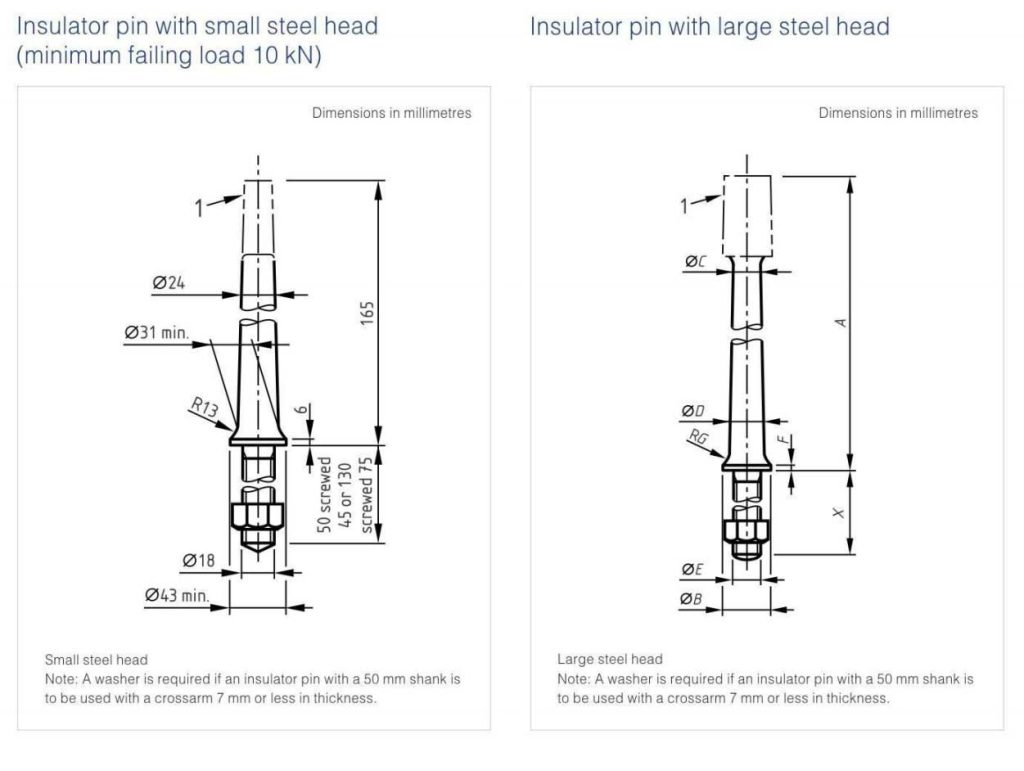

Dimensions of insulator pin with large steel head

| Reference number |

Minimum failing load kN |

A mm |

OB min mm |

0C mm |

ODmin. mm |

OE mm |

F mm |

(RG) mm |

xA mm |

| 26 | 5 | 165 | 37 | 24 | 24 | 18 | 5 | 13 | 50 or 130 |

| 28 | 5 | 230 | 40 | 24 | 28 | 22 | 6 | 13 | 50 or 130 |

| 30 | 5 | 305 | 43 | 24 | 31 | 22 | 6 | 13 | 50 or 130 |

| 27 | 10 | 165 | 43 | 24 | 31 | 18 | 6 | 13 | 50 or 130 |

| 29 | 10 | 230 | 50 | 25 | 37 | 22 | 6 | 13 | 50 or 130 |

| 31 | 10 | 305 | 63 | 27 | 40 | 22 | 6 | 16 | 50 or 130 |

Dimension X to be 50 mm screwed 45 mm, or 130 mm screwed 75 mm.

这是测试文本,单击 “编辑” 按钮更改此文本。

Certificate Display

Factory Tour

Why choose us?

Professional

Professional

Fast Delivery

Fast Delivery

Good Price

Good Price

High Quality

High Quality

FAQs

Who are we?

We are Manufacturer more than 21 years experience in Binzhou City, shangdong, China. We start from 2004, sell to Domestic Market(52.00%), Eastern Asia(25.00%), Africa(10.00%), Mid East(6.00%),Southeast Asia(4.00%),South Asia(3.00%). There are total about 301-500 people in our office.

How can we guarantee quality?

What can you buy from us?

House eletric wire, Anti-aging wire, Solar PV cable, Control cable, Shielded computer cable, Low/Medium/High Voltage power cable, Aluminum alloy cable, Aerial insulated cable, Steel core aluminum standed wire, LSZH cable, Fireproof cable, Wind power cable, EV charging cable, Energy storage cable, Mining cable, etc.

Why should you buy from us not from other suppliers?

hengwang cable company has passed ISO9001 quality management system, ISO14001 environmental management system, ISO45001\German TUV certification\CE certification, the company is a finalist for the state power grid and a national”High-tech Enterprise.

What services can we provide?

Accepted Delivery Terms: FOB,CFR,EXW,FAS,DDP; Accepted Payment Currency:USD,EUR,CAD,AUD,GBP,CNY; Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union,Cash; Language Spoken:English,Chinese,Japanese,German,Russian

If I need customize Packing Cartons, is that available?

Yes, we have production line for packing box and cartons. we can make it according to your special requirement. If you are interested in our goods , please kindly send an inquiry to us !

Contact us to get your quote!

Products

Related Products

our products

NEED HELP

Contact Info

- Email: info@unielectricgrp.com

- Phone: +86 16668093290

- WeChat: +86 16668093290

- WhatsApp: +86 16668093290

- Address: No.26, Zhengzhou City, Henan Province,China

© Copyright 2025 by Uni Electric Group Co,Ltd. All Rights Reserved.